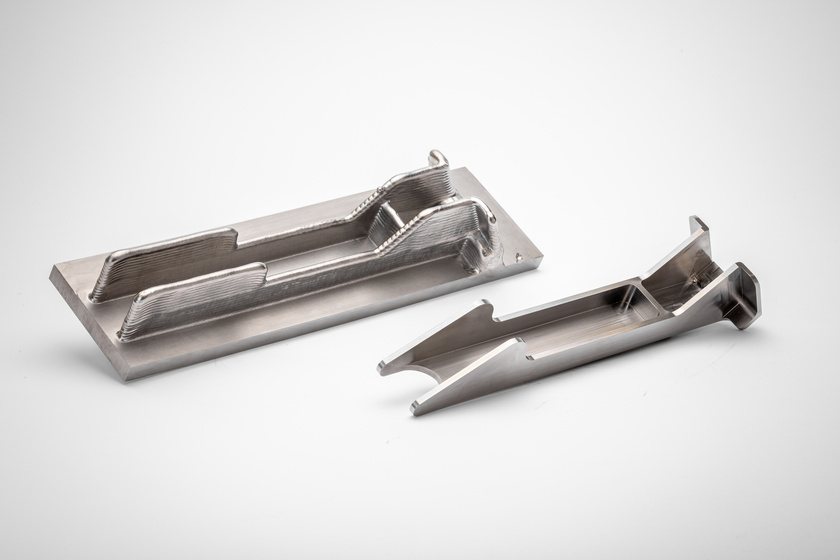

WEBAM for flexible production

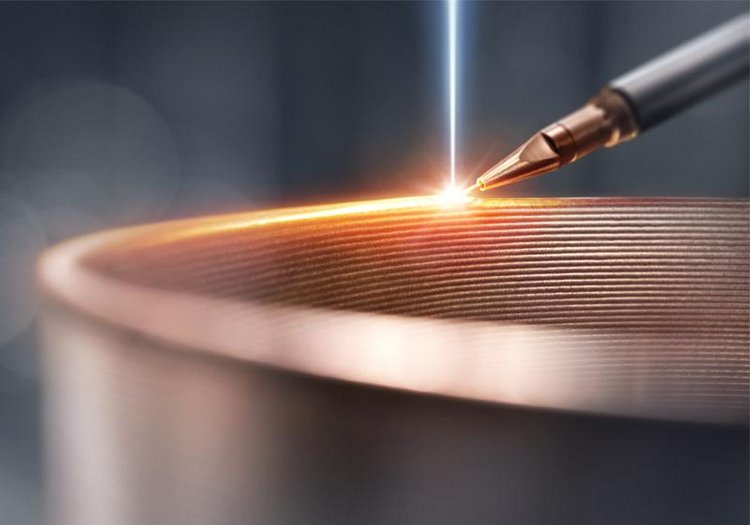

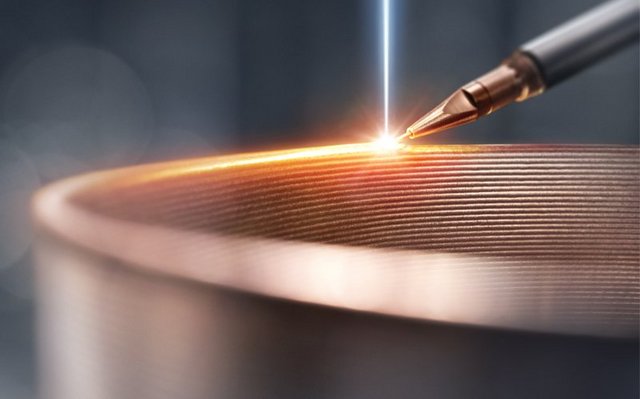

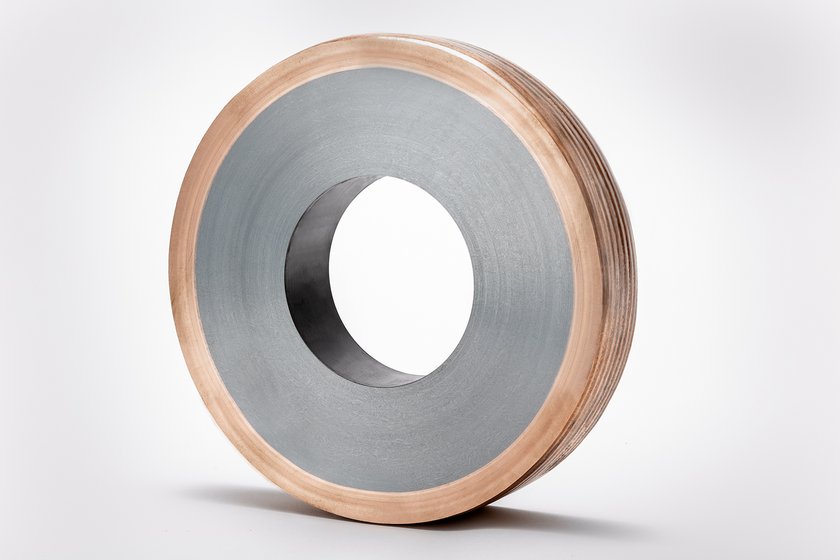

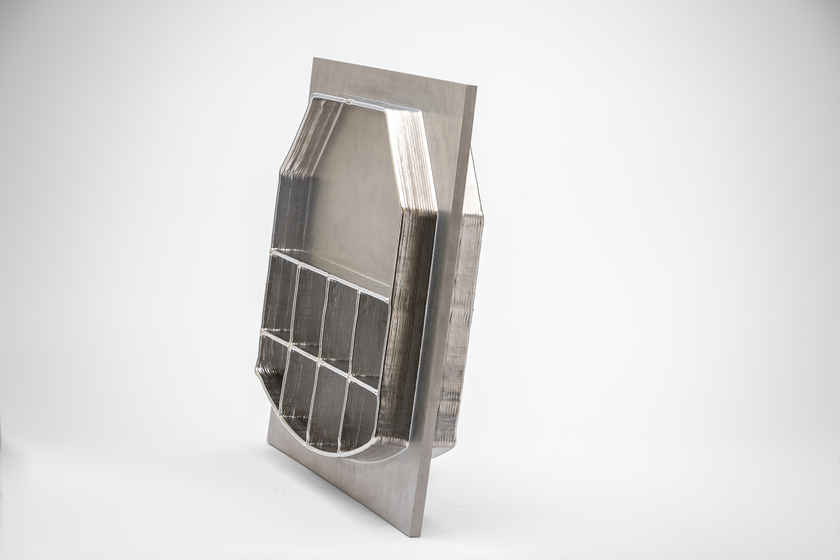

The additive manufacturing of components using an electron beam (WEBAM – Wire Electron Beam Additive Manufacturing) enables faster production times than with other comparable AM processes. Using the principle of wire deposition welding, semi-finished products as well as large metal components can be manufactured in a flexible and highly productive manner – from a batch size of 1 up to serial production.

The production of three-dimensional industrial components is performed by continuously fusing of metal wire within the vacuum of the system PB WEBAM 100. The inert environment prevents the material from being influenced by atmospheric gases. Using the electron beam also enables the creation of near-net-shape workpieces out of high-performance metals and reactive metals in a single process step. Thereby, the process is fast, material efficient and economic. Using our digitally controlled process, all operations can be automated and reproduced. There's another benefit: Upon request, the material can be varied during the process so that the component can be composed of different materials.

In addition, the wire-based PB WEBAM 100 has an open system, whereby all parameters can be looked at and individually adjusted to each other. With the integrated wire feeder developed by pro-beam, a precise adjustment of the wire feed as well as a simple and flexible merging of the wire feeder data with the process data is possible.

Advantages at a glance

- Production of large components

- Faster production times than with other comparable processes

- Production in an inert environment using a vacuum

- Reproducible quality

- Economic due to its material efficiency and reduced waste products

- High variety in materials, incl. difficult-to-weld metals

- Multi-material components