Gilching, November 10, 2021 – pro-beam additive GmbH will be presenting two trendsetting systems at this year's Formnext (November 16 - 19). They are intended to be used in additive manufacturing of metal components and were specially designed for industrial applications.

After pro-beam additive GmbH presented its 3D printing processes last year with WEBAM (Wire Electron Beam Additive Manufacturing) and EBM (Electron Beam Melting) under the slogan "E-Beam Additive goes Industrial", the company is now positioning itself in the AM market as a solution and systems partner. The pro-beam Group has developed a manufacturing system for each of its electron beam processes. These machines optimally respond to the industrial requirements for an efficient production of 3D printed metal components.

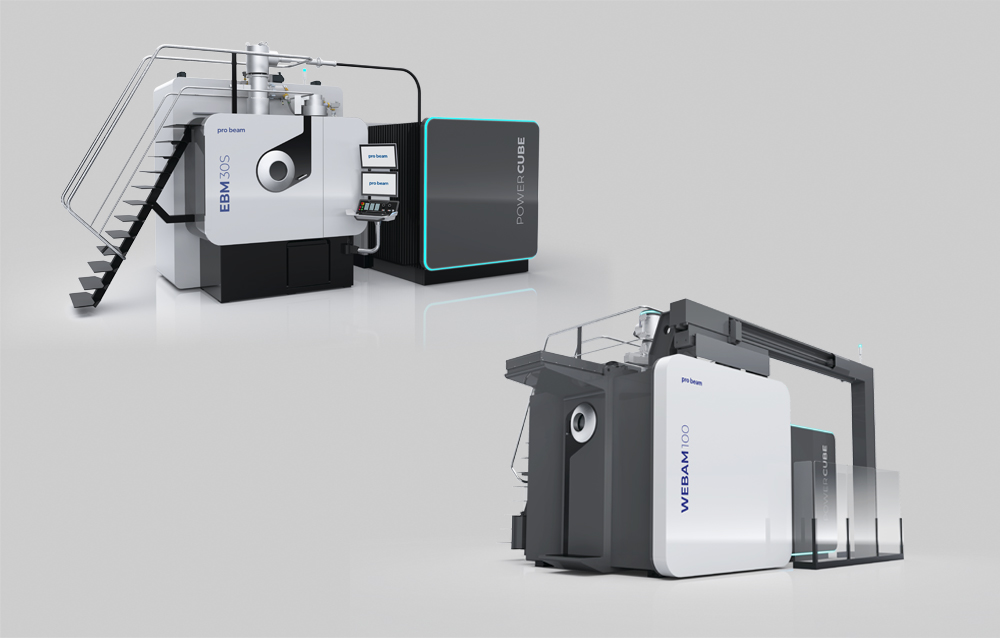

Thus, the wire-based PB WEBAM 100 system enables large components with excellent surface qualities to be manufactured, and users of the powder bed-based PB EBM 30S can achieve maximum process productivity. These machine developments are based on the pro-beam Group's long-standing expertise in the areas of technology development, series production and plant engineering.

"We are proud to launch our AM systems, in which we integrated our technological and plant engineering-specific expertise," says Dr. Thorsten Löwer, CTO at pro-beam, adding "With these machines, we are addressing all those players who not only use additive manufacturing with the electron beam, but also want to view, understand, seamlessly trace and automatically control the particular process, regardless of whether it's an industrial company, university or institute."

PB EBM 30S powder bed-based system – maximum productivity

The PB EBM 30S manufactures small, highly detailed metal components in a powder bed using the electron beam melting (EBM) process specially developed by the company. Thanks to the good resolution and high speed of the electron beam, this process ensures the fast, high-quality production of metal components. In addition, the German contract manufacturing and plant engineering company is relying on a unique deposition strategy that enables a controlled and customized heat distribution. Thereby, component size and geometry play a minor role.

Another highlight of the PB EBM 30S is the new machine concept in which processes are parallelized. This results in an efficient system with the highest possible chamber utilization, without significant auxiliary process times. This implicates maximum productivity for the customer.

Ongoing quality control is indispensable for industrial components. That is why the company relies on a proprietary technology called ELO (Electron Optical Monitoring) for in-situ monitoring. It generates regular, high-contrast images during the manufacturing process by means of backscattered electrons. With these recordings, it is possible to create a so-called digital twin of the workpiece. The ELO data can also provide valuable information for accelerating and improving the process development.

At the same time, the PB EBM 30S impresses with its open system for viewing and adjusting all process parameters and construction data. This kind of transparency ensures flexibility and enables users to develop their own manufacturing processes that can be reproduced repeatably.

PB WEBAM 100 wire-based system – precision in large dimensions

Additive manufacturing with the PB WEBAM 100 gives users the flexibility to make large components from various high-performance metals in a material-efficient manner. This process is also capable to manufacture multi-material components. The robust WEBAM process ensures reproducible quality for a variety of applications: it is suitable for layered structures for both new components as well as structures on existing metal components. The latter is suitable, for example, to repair worn components.

The WEBAM system is available in various sizes and with various kinematics. With high deposition rates (kg/h), this machine enables fast provision of near-net-shape workpieces. The wire feeder developed by pro-beam, which is integrated into the control system, also makes a major difference. It enables a precise setting of the wire feed as well as a simple and flexible integration of the wire feeder data with the process data. Like the EBM system, the wire-based PB WEBAM 100 also operates with an open system that allows the access to all parameters and their individual coordination.

High-performance machines for the AM market

"These pro-beam systems are highly impressive owing to the technological capabilities as well as to their functional design. Our goal is to provide innovative, high-performance and user-friendly systems for industrial applications," explains Markus Kepka, CMO at pro-beam.

pro-beam will be providing a sneak peek as well as more information at Formnext in hall 12.0, stand B19. Onsite you will have the opportunity to speak with pro-beam experts in person.

About pro-beam

The pro-beam Group is a global leader for the electron beam technology. pro-beam provides services and systems for the welding, hardening, micro-drilling, and coating of surfaces. Moreover, the company operates in the field of additive manufacturing and enables corresponding manufacturing processes for metal components. Customers from over 40 countries have been trusting pro-beam solutions for over 45 years. The global company is represented by five locations and more than 430 employees. The company headquarters is located in Gilching, near Munich. More information about pro-beam is available at: www.pro-beam.com

Press Contact pro-beam Group

pro-beam GmbH & Co. KGaA

Zeppelinstraße 26

82205 Gilching

Deutschland

Marlina Schütze, Marketing Stefanie Köhr, Marketing

Tel.: +49 89 899 233 9082 Tel.: +49 89 899 233 9168

[email protected] [email protected]