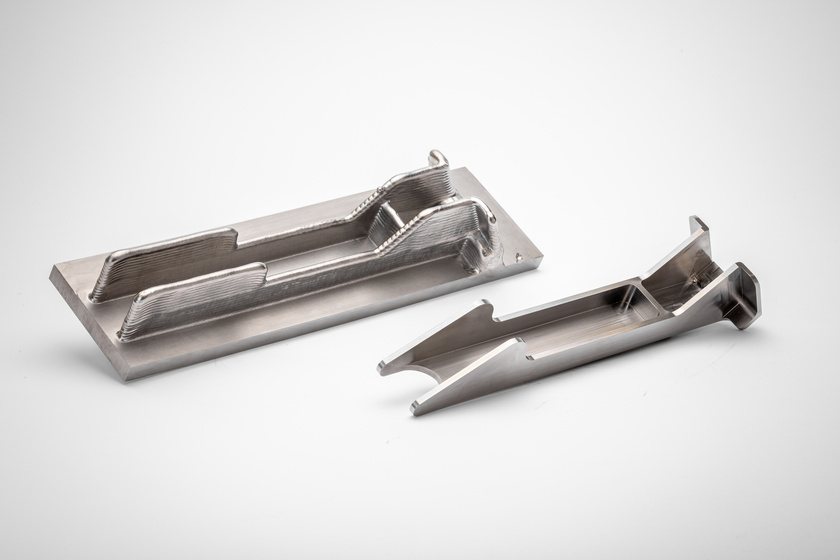

WEBAM for flexible production

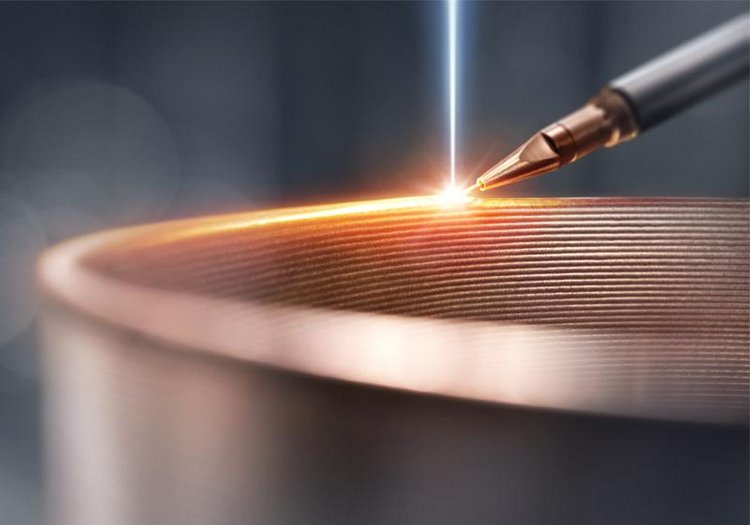

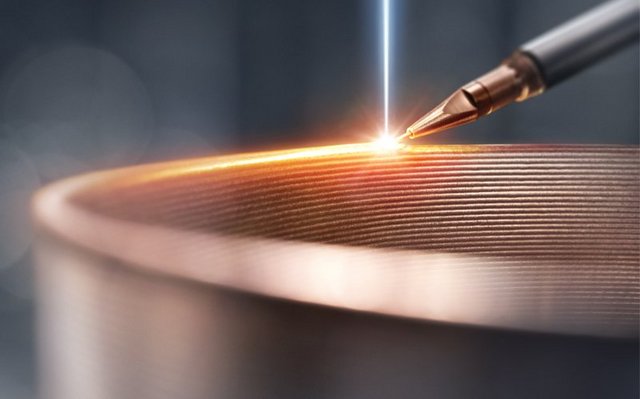

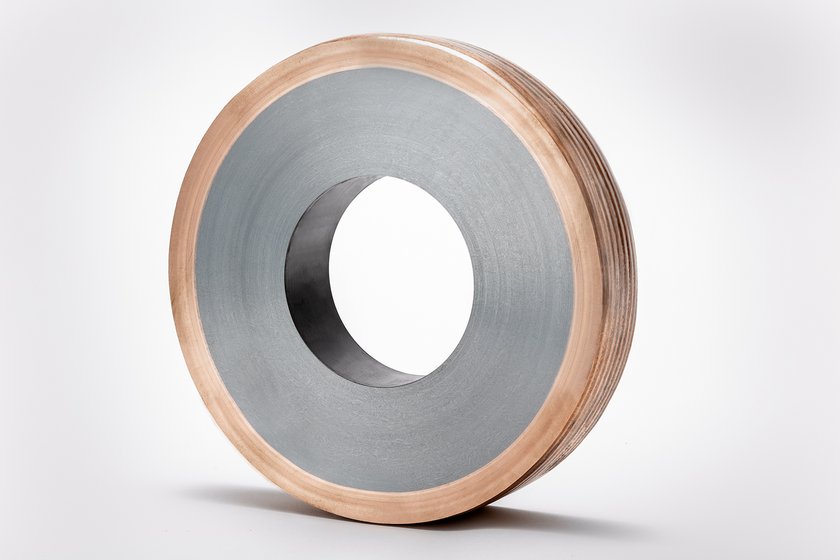

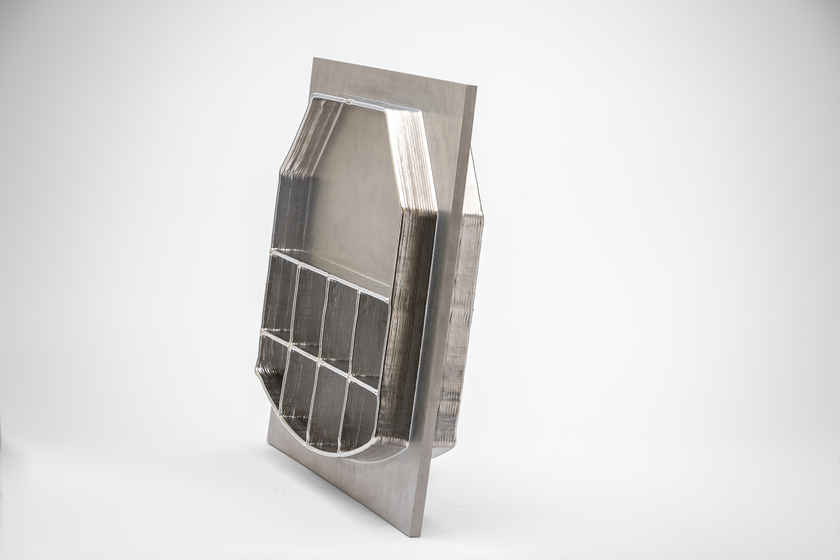

The additive manufacturing of components using an electron beam (WEBAM – Wire Electron Beam Additive Manufacturing) enables faster production times than with other comparable AM processes. Using the principle of wire deposition welding, semi-finished products as well as large metal components can be manufactured in a flexible and highly productive manner – from a batch size of 1 up to serial production.

The production of three-dimensional industrial components is performed by continuously fusing of metal wire within the vacuum of the additive manufacturing machine PB WEBAM*. The inert environment prevents the material from being influenced by atmospheric gases. Using the electron beam also enables the creation of near-net-shape workpieces out of high-performance metals and reactive metals in a single process step. Thereby, the process is fast, material efficient and economic. Using our digitally controlled process, all operations can be automated and reproduced. There's another benefit: Upon request, the material can be varied during the process so that the component can be composed of different materials.

In addition, the wire-based PB WEBAM has an open system, whereby all parameters can be looked at and individually adjusted to each other. With the integrated wire feeder developed by pro-beam, a precise adjustment of the wire feed as well as a simple and flexible merging of the wire feeder data with the process data is possible.

*The machine is available in different sizes.

Advantages at a glance

- Production of large components

- Faster production times than with other comparable processes

- Production in an inert environment using a vacuum

- Reproducible quality

- Economic due to its material efficiency and reduced waste products

- High variety in materials, incl. difficult-to-weld metals

- Multi-material components