Advantages of welding in a vacuum

Where other technologies reach their limitations, the precision welding process ensures optimum results:

- Easy automation: Because the electron beam is a digital tool, joining processes can be easily automated, welding results are reproducible at any time and mechanical properties remain intact.

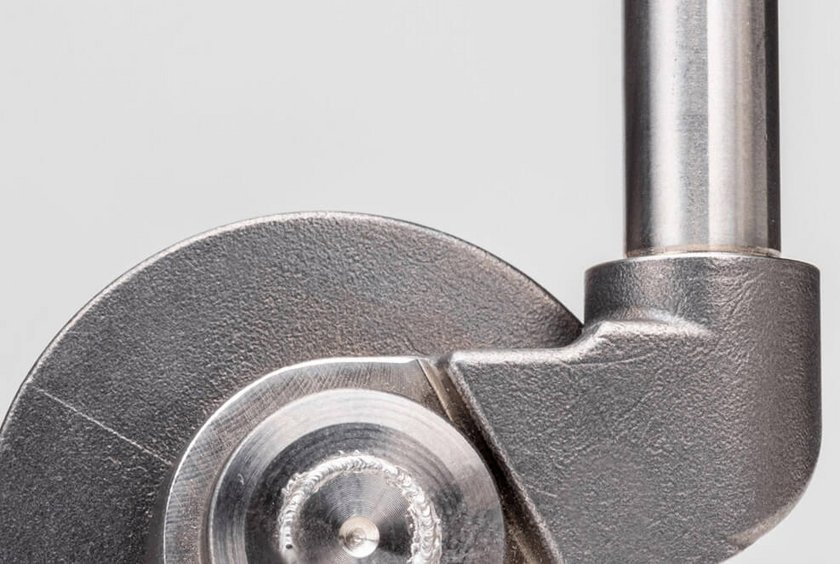

- Flexibility: The electron beam can be made into any shape using magnetic fields to enable the welding of geometrically complex components. This gives engineers a great amount of freedom when it comes to process design and construction.

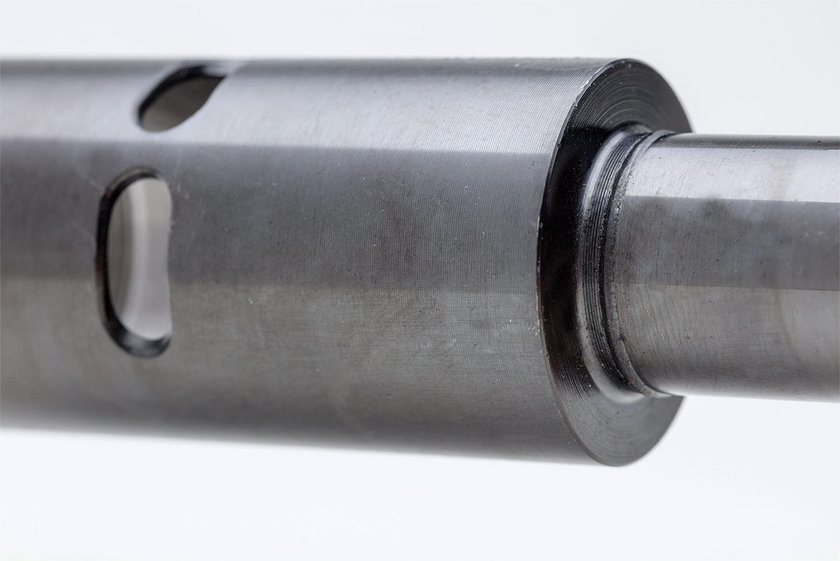

- High efficiency: The process delivers deep, narrow and parallel seams. With simple seam preparation and a weld penetration depth of over 150 mm, electron beam joining is far superior to other thermal processes. This eliminates the need for multiple layer welding or additional material. Oversize is significantly reduced due to near-net-shape processing.

- Maximum precision: Electron beam welding achieves precise results with minimum stress and warping of workpieces.

- High welding speed: Many metallic materials and material combinations can be welded using an electron beam at a higher speed and with practically no ejections. Finished components are ready to install immediately or after only minimal reworking.

Efficient and cost-effective solutions for challenging components

Precise, flexible, easy to automate - these properties make the electron beam process the Number One choice for

- All standard metals, challenging mechanical materials such as titanium, duplex steels, aluminum or hybrid material combinations as well as hard-to-weld steels

- High load-bearing components

- Workpieces with a wall thickness of more than 150 mm

- Components with sensitive internal parts (for example sensors)

What our customers say about us

MT Aerospace AG has been working closely with pro-beam for many years. Together, we have been able to achieve mass production at the highest standards, three times stricter than the norm. This is especially remarkable when seen in the context of a large component with a 6 m diameter and a 70 mm weld seam depth and the use of special aerospace aluminum alloys.

MT Aerospace AG

TOP